- Automotive manuals

- Abarth

- Acura

- Alfa Romeo

- AMC

- Ariel

- ARO

- Astra

- Aston Martin

- ASIA ROCSTA

- Audi

- Austin

- Autobianchi

- Avia

- Bentley

- Bedford

- BMW

- Borgward

- Brilliance

- Bugatti

- Buick

- BYD

- Cadillac

- Caterham

- Chana

- Changan

- Chery

- Chevrolet

- Chrysler

- Citroen

- Dacia

- Daewoo

- Daihatsu

- Datsun

- Ford

- Geely

- Haval

- Hummer

- Hyundai

- Infiniti

- Isuzu

- JAC

- KIA

- Lifan

- Subaru

- Lexus

- Mercedes-Benz

- Mitsubishi

- Peugeot

- Polaris

- Tesla

- Toyota

- Volkswagen

- Volvo

- Volvo Trucks

- Colour Codes

- Fault Codes

- Engine Codes

- Engine Repair

- TRANSMISSION

- ZF

- ALL BRANDS

Chevrolet Tracker Service & Repair Manuals

Content

Quick links to the pages of the book Identification

Abbreviations and conventions

Basic parameters of the car

Precautions for maintenance

Safety measures when working with different systems

Self-diagnosis

Typical malfunctions of cars

Maintenance and general inspection and adjustment procedures

Engine G16A. Mechanical part

The engine is J20A. Mechanical part

Engine H25A. Mechanical part

Engine H27A. Mechanical part

Cooling system

Exhaust system

Ignition system

Fuel Injection System EPI (G16A)

Schematics of electrical equipment

Chevrolet Tracker 1997-2004 - Instructions for use, maintenance and repair.

Chevrolet Tracker 1997-2006 - Instructions for use, maintenance and repair.

Automatic transmission

Arrangement of elements of the electrical part of the control system ((Escudo, Grand Escudo) since 2003). 1 - indicator operating mode of the automatic transmission "POWER", 2 - the indicator of switching off the overdrive, 3 - the frequency sensor rotation of the output shaft of the gearbox, 4 - the switch of the prohibition of starting the engine, 5 - the switch-on sensor mode "4L", 6 - selector switch mode automatic transmission, 7 - switch upshift, 8 - connector for connecting the tester, 9 - automatic transmission control unit, 10 - electrical control unit body, 11 - the gearbox input speed sensor, 12 - engine and air conditioning control unit, 13 - the block of valves, 14 - the gauge №1 temperatures of a working liquid, 15 - electromagnetic valve No. 2 of the clutch control, 16 - solenoid valve for locking the torque converter, 17 - electromagnetic valve number 3, 18 - sensor number 2 fluid temperature automatic transmission, 19 - solenoid valve pressure control in the main line, 20 - solenoid valve 1 of the clutch control, 21 - solenoid valve № 1, 22 - solenoid valve

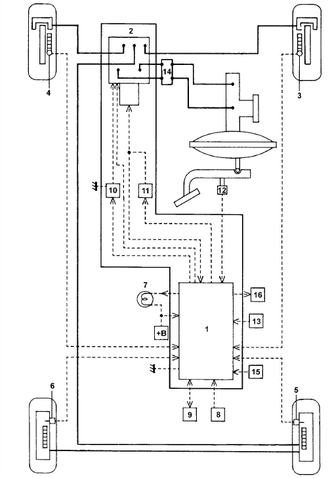

Electrical elements of the system ABS.

1 - electronic control unit ABS,

2 - pressure modulator,

3 - the gauge of frequency of rotation of forward

right wheel,

4 - the gauge of frequency of rotation of forward

left wheel, 5 - Rear Speed Sensor right wheel,

6 - the gauge of frequency of rotation of back

left wheel, 7 - ABS system indicator,

8 - connector for connecting the tester,

9 - the diagnostic socket,

10 - protective relay,

11 - electric pump relay,

12 - the switch of stoplights,

13 - deceleration sensor,

14 - pressure regulator,

15 - all-wheel drive switch,

16 - electronic control unit engine,

17 - full switch drive,

18 - electronic control unit engine.

The engine stalls ...

A very unpleasant problem, which is often enough

meets on models with engine J20A (2,0 l) in the summer

period - the engine periodically stalls during

traffic in road congestion at high temperatures

outdoor air. If the engine stalls, then start

it succeeds only after 10-20 minutes, while the work

The included engine does not cause any complaints,

the readings of the measuring devices are normal,

as well as the levels of technical fluids. The problem is aggravated

also the fact that this malfunction -

"floating" and when diagnosing a car on SRT, as

rule, to identify its cause is not possible. Often, coming to

the solution of the problem "stereotypically", the representatives of SRT

offer to repair the fuel system

(replacement of fuel pump), replace filters, spark plugs,

clean the throttle, etc.

However, the most common cause of this malfunction

- incorrect operation of the distribution sensor

motor shaft caused by overheating

sensor. Because of the incorrect (or temporarily absent)

signal from the distributor

shaft failure of the ignition and injection systems

fuel. In this case, the engine will only start,

when the sensor cools down and starts to function.

Remedy is only possible by replacing

sensor to a new one. It should be noted that in the catalog

spare parts SUZUKI for engine J20A this sensor

is only available as an assembly (catalog number 33100-

65D00) and costs about $ 300, but the same sensor is installed

and the G16A engine for which it is available

separately (catalog number 33220-50G02).

Note: since, most likely, overheating

the camshaft position sensor

due to poor heat transfer in the rear of the motor

compartment, some car owners manage to get rid of

from this problem by removing the metal

black plug (fixed by two

bolts) located in the central part of the motor

under the windshield, thereby

improving heat transfer.

jacj (Friday, 25 August 2023 19:21)

please can i see it